Introduction

In Korea, the total area under strawberry cultivation is 6,403.4 ha, and its annual production is 194,513 tons. Furthermore, Korea is the sixth largest producer of strawberry globally. The production of strawberry has been increasing annually (MAFRA, 2016). It is noteworthy that the greenhouse cultivation of strawberry covers 6,306 ha, which accounts for 98% of the total strawberry cultivation area. The cultivation of strawberry under artificial structures has increased, as it improves the quality of fruits compared with that by the conventional method. Furthermore, the temperature, humidity, light, and carbon dioxide concentration can be easily controlled in these artificial structures for year-round production (Nam, Kim & Seo, 2014). In Korea, which has four distinct seasons, strawberries are categorized into the following types: (1) one-season flowering strawberries that bear fruits after the differentiation of flower bud under low temperature and short-day condition and (2) ever-bearing strawberries that bear fruits after the differentiation of flower bud under high temperature and long-day condition. Based on the farm management type, appropriate strawberry varieties are selected and cultivated. In particular, during high temperature and humid season conditions in Korea, the fruit quality parameters of everbearing strawberries, such as fruit size and sugar content, are lower than those of one-season flowering strawberries that are produced during winter, thereby decreasing strawberry production in summer (MAFRA, 2010-2016). The optimal growth temperature for ever-bearing strawberries is below 20°C. When the temperature exceeds 25°C, growth is delayed, and when it is more than 30°C, growth stops. In addition to, production of mushrooms, including oyster mushroom, is 167,366 tons in Korea, accounting for 381.6 billion won; the number of farmhouses cultivating mushrooms is 3,361. (MAFRA, 2016). The concentration of carbon dioxide (CO2) generated during mushroom cultivation after inoculation and during growth in growth chamber is approximately 1,000-5,000 ppm. The temperature of mushroom cultivation systems varies depending on the type of mushroom cultivated (enokitake: 2°C; oyster mushroom: 18°C). Thus, the aim of this study was to develop a technology to improve strawberry growth and produce high-quality fruit using a moveable three-tier cylindrical bed system with cold air containing a high concentration of CO2 from mushroom cultivation thus minimizing high-temperature stress (Jun et al., 2008;Kim et al., 2010a, 2010b; Kim & Seo, 2012)

Materials & methods

1. Cultivars

The ever-bearing (summer) strawberry cultivar ‘Charlotte’ (Ciref, Maison, France) was chosen for this experiment.

2. Cultural condition

The ever-bearing strawberry cultivar ‘Charlotte’ was planted on June 1, 2017, and their growth and fruit production were monitored and analyzed until September 30, 2017. The artificial bed soil (The zone Corp., Jincheon, Korea) used was a product exclusive for strawberries. After covering with a polyolefin film (ILSIN Chem. Com., Ansan) with a side height of 4.5 m in the 1-2 w type standard plastic green house, 5 lines (length 20m) of three-tier cylindrical bed and a high bench bed were respectively installed. From June 21st to September 30th, every day from 09:00 to 19:00, using the cool air emitted from the mushroom cultivation house, partial cooling was performed around the crown of the ever-bearing strawberry. When the inside temperature of the house became 28 degrees or more. The both side-windows and skylights were automatically open. On the inner side of the cylindrical beds, pipes of diameter 22mm were installed with nozzles attached at every 50 cm to spray the nutrient solution. The spraying time was adjusted to once every 5 min. Sixinch net pots were simultaneously drip irrigated by inserting two drip pins in each pot. The controls (high-bench bed) were planted 20-cm apart, every two weeks. The nutrient solution composition and application methods used PBG (Sonneveld, C., 2002) nutrient manual.

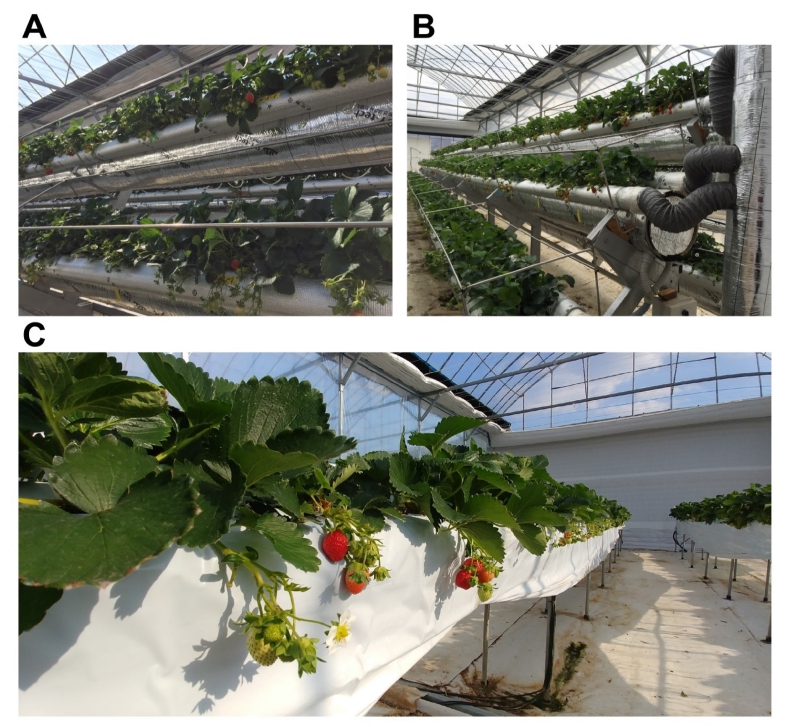

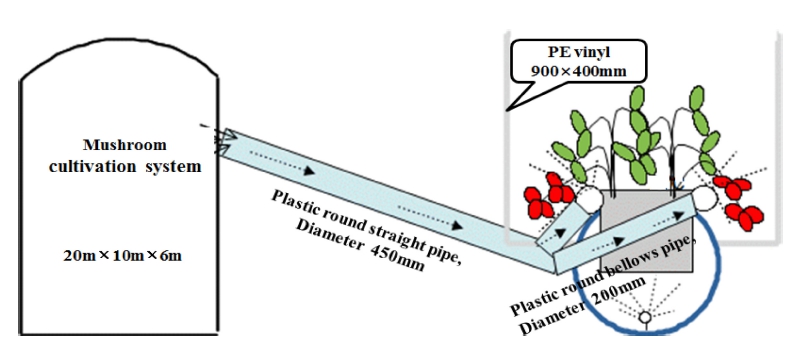

3. Installation of the moveable three-tier cylindrical bed and local air-conditioning unit and duct

To observe the effects of producing strawberries using the gas emitted from mushroom cultivation, a cylindrical plastic pipe of diameter 300mm was fabricated to create a moveable three-tier cylindrical bed that can be automatically tilted. The moveable multi-tier cylindrical bed was configured and tilted at an angle of 60° to eliminate any shading that occurs on the lower tiers and to ensure even sunlight distribution. The bed was stacked vertically during growth and harvest (Fig. 1). The cylindrical bed system was of 18m length and 2m height, with a distance of 50cm between the tiers. In addition, holes of 15cm diameter, spaced 3cm apart, were created on the upper side of the beds to insert net pots of 15cm diameter (6 inch) and plant strawberries every two weeks.

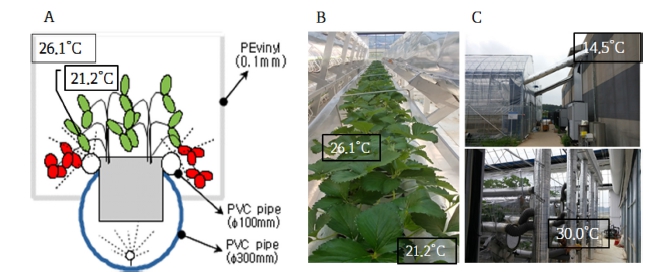

To increase the cooling effects of the air emitted during mushroom cultivation system, a localized cooling system was installed as depicted in Fig. 2 and Fig. 3. Vinyl tunnels were created by securing a rectangular steel frame on either side of the cylindrical beds and wrapping them with 0.1-mm polyethylene (PE) vinyl, to ensure that the air from the mushroom cultivation house was transferred directly to the vinyl tunnels. In addition, pipes of diameter 100mm were installed on either side of the net pots above the cylindrical bed, and 7- mm diameter holes were made at equidistance to ensure that the air from the mushroom cultivation house is discharged in the direction of strawberry crowns and flower clusters. These pipes were connected to the main pipe.

To monitor the temperature, CO2 concentration, photosynthetic photon flux (PPF), and electrical conductivity (EC) of the nutrient solution, a temperature and humidity recorder (T&D Corp., Matsumoto, Japan), a CD-200M CO2 sensor (ELT-Sensor Corp., Bucheon, Korea), an irradiation sensor (STL Corp., Anyang, Korea), and an EC sensor (Mirae-SC Corp., Seoul, Korea) were installed inside the localized cooling and heating system and on the raised beds, respectively. The growth environment data were measured and collected at fixed intervals. In addition, the chlorophyll content of the leaves was measured with a SPAD- 502 chlorophyll meter (Konica Minolta Inc., Tokyo, Japan) and the photosynthetic efficiency was analyzed with a LI- 6400 portable photosynthesis system (LI-COR Inc., Lincoln, USA) in the middle leaves of the strawberry plants. The temperature around the plant was measured using a thermographic camera (Fluke Corp., Washington, USA). The plant length, leaf number, flower number, normal fruit number (NFN), defective fruit number (DFN), fruit mass, fruit size, and fruit number were measured according to the Rural Development Administration (RDA) Agricultural Testing and Research Standards (RDA, 2012).

Results and Discussion

1. Temperature distribution in the locally cooled beds

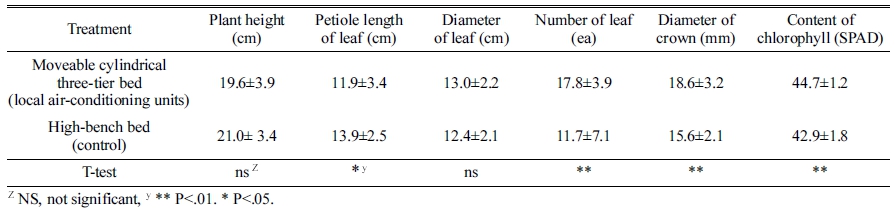

During the hot season from July to mid-September, the day and night temperatures of the mushroom cultivation system, strawberry greenhouse, outer ambient air, and different types of beds were monitored (Fig. 4). During daytime, the mean temperature of the mushroom cultivation system, greenhouse, and ambient air was 14.5°C, 30.0°C, and 26.1°C, respectively. The maximum and minimum strawberry crown temperatures in the high-bench beds were 33.7°C and 19.5°C, respectively, with a mean temperature of 27.2°C. Furthermore, the maximum and minimum strawberry crown temperatures in the cylindrical beds were 25.3°C and 17.5°C, respectively, with a mean temperature of 21.2°C, which is 6°C lower than that of the high-bench bed.

Fig. 4

Change into day (A) and night (B) temperature by local air conditioning in plastic house. a: The inner temperature of mushroom house, b: The strawberry crown temperature of high bench bed. c: The strawberry crown temperature of movable 3-tier cylindrical bed. d: The temperature of plastic house. e: The temperature of outside.

At night, the mean temperature of the mushroom cultivation system, greenhouse, and ambient air was 14.2°C, 22.1°C, and 22.3°C, respectively. The maximum and minimum strawberry crown temperatures in the high-bench beds were 27.3°C and 15.9°C, respectively, with a mean temperature of 21.6°C. Furthermore, the maximum and minimum strawberry crown temperatures in the cylindrical beds were 21.0°C and 15.1°C, with a mean temperature of 17.9°C, which is 3.7°C lower than that of the high-bench bed.

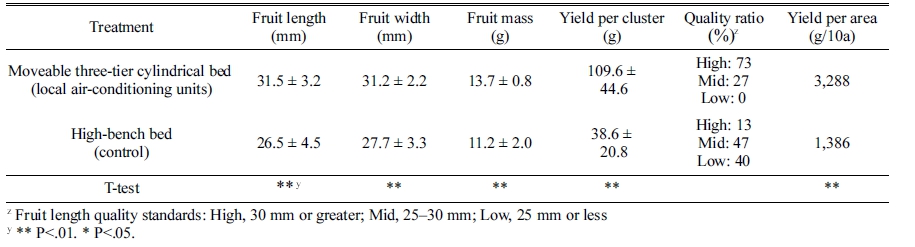

At 2 PM on July 1, 2017, thermal images were captured from the cooling and heating system on the inner side of each tier, and compared with those captured from the highbench bed. In the cylindrical bed, the minimum temperature was 20.0°C in the lowest tier (Tier 1), 23.6°C in Tier 2, and 25°C in Tier 3, showing an increasing trend with height. Notably, the temperature of all the three tiers was lower than the minimum crown temperature of 29.6°C in the high-bench bed. The thermal images are shown in Fig. 5.

Fig. 5

The image of around the coronal temperature for strawberry by thermo-graphic camera (A) Tier 1 of the moveable cylindrical bed (local air-conditioning units) (B) Tier 2 of the moveable cylindrical bed (local air-conditioning units) (C) Tier 3 of the moveable cylindrical bed (local air-conditioning units) (D) High-bench bed (control).

2. Changes in PPF

The mean diurnal PPF was monitored for 12 h between 6 AM and 6 PM, as shown in Fig. 6.

The mean intensity of radiation of the high-bench bed, from tier 3 to 1 of the cylindrical bed were 306, 305, 232 and 175μmol·m-2·s-2, respectively. The PPF in the high-bench bed and tier 3 of the cylindrical bed exhibited similar trends, and compared to the high-bench bed, the cylindrical bed (Tier 2) tended to decrease by 24% and the Tier 3 decreased by 43%. Depending on the position of the sun, there were negligible amounts of shade on the bed not only in the vertical position, but also in the tilted position, resulting in a difference in irradiance reaching the strawberries in each tier.

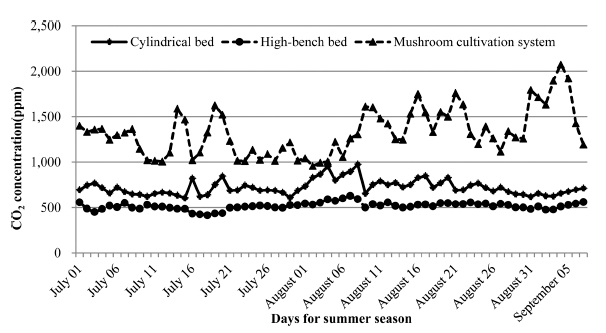

3. Changes in CO2 concentration

The mean CO2 concentration in the mushroom cultivation system was 1,437ppm, and that in the localized cooling system of the multi-tier cylindrical bed(Tier 2) was 741ppm, on the other hand high-bench bed was 534ppm during summer period (Fig. 7). The result that the rate of increase of the net photosynthetic rate at the concentration of 500-700ppm when the carbon dioxide is applied under 4- 10klux weak light at the 25°C temperature reported by Jeong & Yeoung (1995) is similar to that of the CO2 supplied concentration in the multi-cylindrical bed from mushroom cultivation system. The results showed that the improvement of yield compared to the high-bench bed was also the same. As CO2 is critical for photosynthesis and the growth and production of strawberries, several high-value horticultural crop farms apply carbonic acid to expedite plant growth. In the secondary incubators of the mush- room cultivation system, where inoculation was carried out partially, the emitted gas had a CO2 concentration of 1,000- 2,200 ppm.

4. Temporal changes in photosynthetic efficiency

On July 1, 2017, the temporal changes in photosynthetic efficiency, which is affected by the PPF of the strawberry greenhouse and leaf surface temperature, are shown in Fig. 8. The temporal pattern of photosynthetic efficiency was similar to that of PPF and leaf surface temperature.

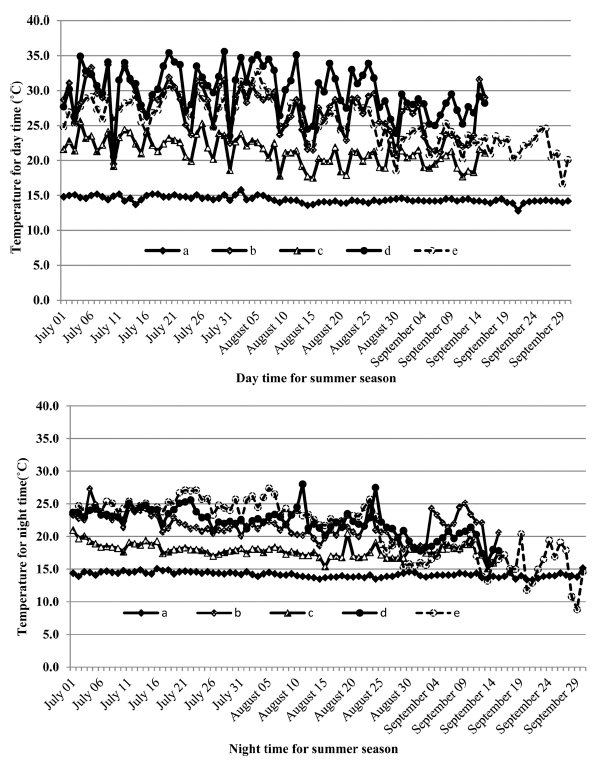

5. Strawberry growth characteristics

The growth characteristics of the strawberries planted on June 2, 2017 and grown in the multi-tier cylindrical bed with the localized cooling and heating system until September 15, 2017 are shown in Table 1. The strawberries in the multi-tier cylindrical bed exhibited a mean plant height, petiole length, leaf diameter, crown diameter, and chlorophyll content of 19.6cm, 11.9cm, 13.0cm, 18.6mm, and 44.7 SPAD value, respectively, and those of the strawberries in the high-bench bed were 21.0cm, 13.9cm, 12.4cm, 15.6mm, and 42.9 SPAD value, respectively. In the present study, superior growth trends, including increased flower cluster emergence and reduced DFN, were observed in strawberry cultivated in the three-tier bed system. Ganmore-Neumann and Kafkafi (1983) reported that the root mass, leaf numder and leaf area decrease when the strawberry root temperature reaches 32°C. Furthermore, Utagawa, Ito & Gomi (1989, 1991) showed, using the nutrient film technique (NFT), that the cultivation of everbearing cultivars in a culture medium at 23°C also decreases root mass, nutrient uptake rate, and photosynthetic rate. Moreover, Lieten (1997) has reported that higher temperatures have increasingly negative effects on vegetative growth of strawberry. In the present study, we used a modified three-tier growth system utilizing cold air emitted from a mushroom cultivation system with periodic nutrient supplementation, to enable the temperature of the nutrient medium and leaves to stay < 25°C, thus ensuring normal strawberry growth.

6. Fruit setting characteristics, sugar content, and acidity

The strawberries planted on June 2, 2017 were examined on August 31, 2017. The results of flower number, normal fruit number (NFN), defective fruit number (DFN), and sugar content with different bed configurations are shown in Table 2. The strawberries in the multi-tier cylindrical bed had 6.7 flowers per flower cluster, NFN of 3.1 ea per flower cluster, DFN of 3.5 ea per flower cluster, sugar content of 8.8° Brix, and acidity of 0.8%. The strawberries in the highbench bed had 6.3 flowers per flower cluster, an NFN of 2.3 ea per flower cluster, a DFN of 4.0 ea per flower cluster, sugar content of 7.9° Brix, and acidity of 0.8%. Compared with those of the high-bench bed control, the multi-tier cylindrical bed had higher number of flowers per cluster and NFN, and the sugar content was 0.9° Brix higher. However, the high DFN in both the treatments could be attributed to the intrinsic characteristics of the ‘Charlotte’ cultivar. When CO2 was applied to tomato, the sugar content, the ratio of sugar content to acidity increased and increased the yield by 35% compared to the untreatment (Hicklenton & Jolliffe, 1978). The supply of CO2 to the cylindrical-bed of this study was similar to the tendency of the sugar content and the ratio of sugar content to acidity to increase.

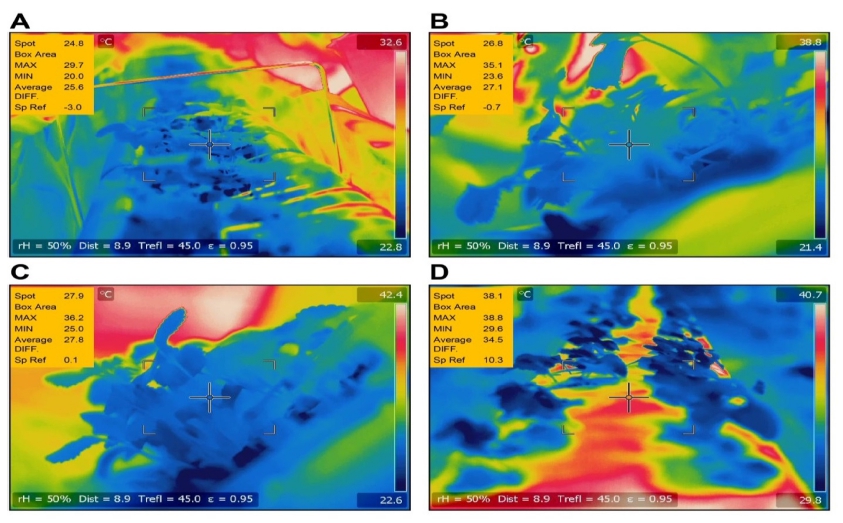

7. Fruit characteristics and quantity

The size, quality, and quantity of strawberry fruit of two obtained from different bed configurations were examined, and the results are presented in Table 3. The strawberry fruits in the multi-tier cylindrical bed had a mean fruit length, fruit width, fruit mass, yield per cluster, high-quality ratio, and mid-quality ratio of 31.5mm, 31.2mm, 13.7g, 109.6g, 73%, and 27%, respectively. However, the strawberries in the high-bench bed had a mean fruit length, fruit width, fruit mass, yield per cluster, high-quality ratio, mid-quality, and low-quality ratio of 26.5mm, 27.7mm, 11.2g, 38.6g, 13%, 47%, and 40%, respectively. Overall, the quality and quantity of the strawberries from the multi-tier cylindrical bed with localized cooling and heating treatment were superior to those from the highbench bed treatment. Generally, the temperature of the artificial nutrient medium does not fall drastically like the interior temperature of the raised bed or the three-tier bed; however, studies have shown that cooled air expedites flower cluster emergence and fruit production (Takaichi et al., 2007). This is due to the acceleration of differentiation at low temperatures, subsequently inducing flowering. Wagstaffe and Battey (2004) reported that although the fruit number of ever-bearing strawberries increases even at 27°C, the size and yield decrease at temperatures 23°C or higher. Furthermore, Kumakura and Shishido (1995) reported that the suitable growth temperature for ever-bearing cultivars is 20°C-25°C. So, the localized cooling method can maintain the root and leaf temperature of strawberry at 25°C, and with regard to the economic efficiency, such as increase in yield, an efficient cooling method can be applied to enable summer strawberry production by using cold air from the mushroom cultivation system.